Intelligent Process Automation of Things (IPAoT)

One of the most compelling aspects of the IoT revolution is the reference architecture that depicts end-to-end component interactions and dataflow for robust business value. There are several alternative reference architectures for IoT. Most are IoT platform specific. IoT solutions need to generate returns and in almost all cases real business value involves people. Interestingly it also involves processes.

To set the stage for IPAoT, as a reminder especially of the role processes in IoT, remember how Cisco described Internet of Everything with a holistic view:

Things: Connected devices, each with a unique addressable URL over the Internet.

People: Participants in end-to-end processes or dynamic cases, in partnership with Things.

Process: At the most basic level, coordination of multiple activities or tasks for a business objective. The participants in processes will include people, Things, enterprise applications, and business partners.

Data: Generated by Things at an even greater rate than people or applications, IoT data needs to be analyzed and responded to, often in real-time.

The processes with IoT orchestrate people, connected devices, enterprise applications and data – end-to-end. In a previous article on Process, Data, Digital Transformation we expanded upon the Road to IoT Success through Digital Process Automation – that has evolved from Business Process Management (BPM).

AWS IoT Architecture

Many components and technologies are used to support IoT/IIoT use cases end-to-end: from the Edges to the Enterprise - involving People, Processes, Analytics (from Thing Data), and, of course, Connected Devices. Functions such as Edge Communications and Security are essential components for IoT. There are multiple tiers from the edge networks, through the cloud, to the enterprise and people using IoT applications typically via mobile devices. IoT Reference Models or Architectures illustrate the layering and interaction of the various components that comprise an end-to-end IoT platform or framework. Some are IoT platform-specific. The following shows the IoT Reference Architecture of AWS IoT, which, in addition to Azure IoT and others, is an IoT Platform industry leader (there are more than 600 IoT platforms and increasing!). The AWS IoT capabilities are realized through the AWS IoT Data Services, Control Services, and Device Software.

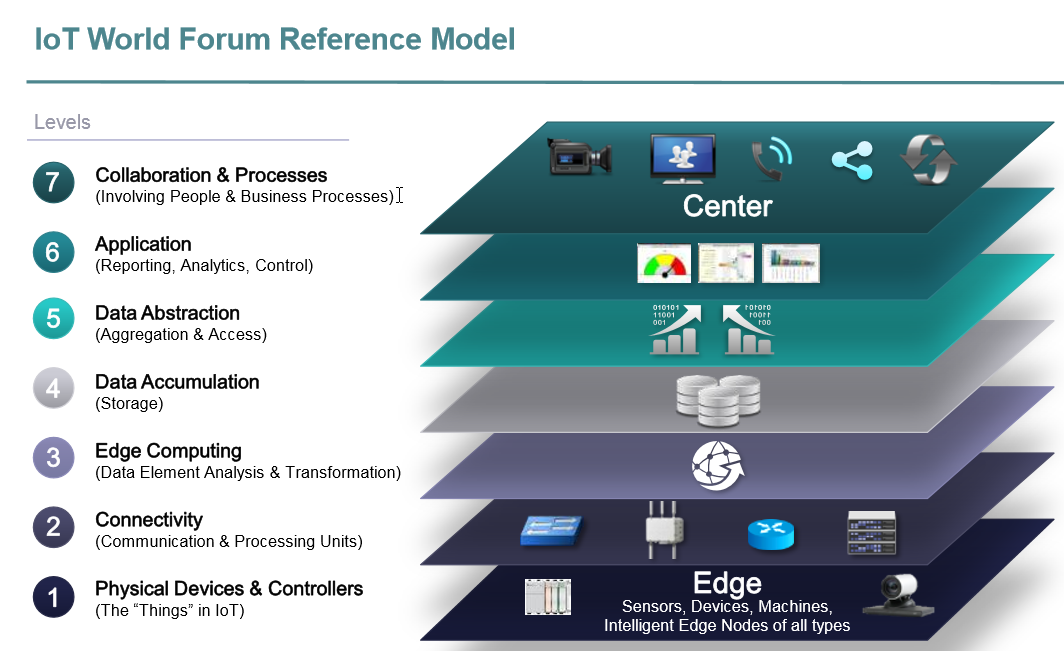

There are also IoT reference models that pertain to IoT consortia or standardization bodies. My favorite is the IoT World Forum’s Reference Model. This 7 level architecture reference model puts collaboration and Business Processes at the top of the multi-level architecture for IoT.

IoT is about connectivity of increasingly intelligent devices through sensors and actuators. The foundation for connectivity, balancing range, and power supply considerations is, of course, critical. There are several components in the overall stack and multi-tier architectures of IoT. The lowest levels include physical devices and systems. It is precisely this cyber-physical/connectivity that is laying the foundation of the IoT era. Other layers include edge computing – see the following on Intelligent IoT Edge Computing - as well as the data accumulation and analysis layers. But the often-elusive ROI (aka business value) of IoT is achieved at the top layer – the “action” part that we mentioned earlier – involving process orchestration of People, Connected Devices (aka IoT/IIoT), trading Partners, and Enterprise Applications (aka Systems of Record).

Telehealth with IoMT

To illustrate the importance of process automation – and especially intelligent processes – consider the recent spike in Telehealth due to Covid-19. What is telehealth in the Covid-19 era? IoT – with connected medical devices – plays a significant role: “The Internet of Things (IoT) has extended traditional videoconference visits to enable practitioners to remotely monitor patients’ blood pressure, oxygenation levels, pulse and other key metrics.” More importantly, it is not just about sensing. It needs coordination and cooperation – not just technology or virtual visits. In other words, the evolving telehealth needs processes. As quoted in the article by one of the experts Dr. Peter Fleischut, “It’s about people, process and technology … It’s probably 80% people, 15% process, and 5% technology.”

Intelligent Insights to Process Action

Not surprisingly Artificial Intelligence has emerged as an increasingly important enabler of connected Things: from Natural Language Processing in smart speakers to predictive maintenance of connected devices to AI applied in a plethora of advanced deep learning applications. A perfect storm of technological advances in computing, databases, and networking has caused the emergence of AI as one of the most significant digital transformation trends. Another trend of course is IoT. But the “Intelligence” in AI (and HI – as in Human Intelligence), needs a context – the collaboration and processes. It is about people, processes, connectivity technology, and Intelligence – still, people and process being the most important.

Insight to Intelligent Process Automation (Action)

For connectivity technology, IoT is generating enormous amounts of data. We are inundated with information from connected devices – both in consumer and industrial contexts – and it does not appear to be letting up any time soon. Connected devices are becoming increasingly significant sources of information: Big Data will is becoming “Thing Data.” Over time, the Thing data will be stored, analyzed, and mined for models that reflect insights – that can then be acted upon, such as analytics model that can predict a device will fail before it happens.

The following illustrates the continuous improvement loop from Insight to Action. At the bottom, you have the raw data emanating from connected IoT/IIoT devices. The raw data could also include customer transaction data, trading partner data, and even Blockchain transactions. The data is organized and analyzed, leveraging a plethora of SQL and NoSQL intelligent databases – the latter, especially for the management of Thing Data. Then various patterns are detected through data mining, predictive analytics, and machine learning techniques. The AI models are insights that can then be operationalized in end-to-end Process Automation solutions. More specifically, the Action leverages the Intelligence harvested from the data or from human experts and then executes them in through Automated Processes.

IPAoT ROI

The Return on Investment (ROI) of IPAoT emanates from the ROI of Process Automation and IoT. Process Automation addresses process orchestration involving enterprise applications, people, and increasingly the connected device (IoT) silos. As noted above in the IoT World Forum reference architecture, the top and most crucial level business value pertains to business process and collaboration.

Process Automation ROI

The ROI of Process Automation emanates from three complementary and interdependent areas:

Process efficiency in planning and deploying innovations: The Low Code/No Code model-driven platform of IA enables this efficiency for rapid innovation. The continuous innovation and deployment involve four Digital Transformation methodologies: Design Thinking, Agile, DevOps, and Operational Excellence.

Process efficiency in automated execution: The spectrum of automation summarized above – from robotics to AI-assisted to knowledge worker participation – is critical for resolving manual handoffs and silos. The completion and resolution of end-to-end value streams can be optimized from days to hours due to process automation.

Process efficiency through monitoring and improvement: Out of the box business activity monitoring dashboards, reports, and automated alerts dynamically monitor if work is processed on time, contractual SLAs are being met, and if processes are running optimally. These are actionable monitoring reports – where managers, for instance, can re-assign tasks from under-performers to others. Alternatively, automated business logic (aka business rules) can act in real-time.

IoT ROI

IoT also has many opportunities for ROI. The connectivity of devices has an impact both on next-generation digital transformation applications that leverage IoT/IIoT connectivity as well as the maintenance of the connected devices (e.g., connected vehicles). Here are some of the areas, especially in Industry 4.0 – both in Smart Manufacturing as well as after-market services:

Subject or Purpose Monitoring and Responding: Connected devices in many application domains have a subject or specific purpose: monitoring to optimize insurance of Smart Homes, wellness tracking, health monitoring, Smart City transportation, connected car applications in numerous Car-to-X (Car, Infrastructure, OEM) – to name a few.

Connected Asset Monitoring and Responding: Another compelling ROI opportunity is the ability to monitor the status or condition (vibration, temperature, pressure, readings, etc.) of the connected asset (e.g. a connected vehicle or a Smart Manufacturing robot). Subsequently and then take action. Here the ROI is from the event-action. Notice the action will involve a process orchestrating people and Things. Sometimes, multiple sources of sensing can be correlated and acted upon—for instance, elevated levels of Carbon Monoxide from numerous sensors in a plant or a field.

Data Monetization: Connectivity and aggregation of data pertaining to customers, connected devices, plants, cities, and others provide huge opportunities for data monetization. As we noted above, Big Data is becoming Thing Data. There are many challenges in the ownership of the Data and its monetization. Many Insurance companies – especially in automotive - are effectively leveraging data to adjust Insurance cost depending on how you drive, where you drive, who drives, etc. Even the speed of connected vehicles and their maintenance could be monitored.

Predictive Maintenance: Traditional maintenance tends to be reactive: responding to failures in equipment or devices after the fact. The next maintenance optimization option is preventive maintenance. This empowers operators to carry out continuous maintenance – often based on the recommendations of the manufacturers. Beyond preventive and leveraging analytics, predictive maintenance discovers potential options for the future maintenance of the asset. With AI analytics, it is possible to determine the remaining useful life of a device and take pro-active predictive action before it breaks. There are many sources of data for predictive maintenance. Automatic discovery and then deployment of AI predictive models can yield substantial cost reduction benefits.

Conclusions

IPAoT is the next phase in the evolution of IoT! Connectivity of devices in our homes, offices, and industries is ubiquitous. Connectivity is exploding. Several technologies such as 5G, Cloud, Blockchain, and AI are critical catalysts in the pervasiveness of robust and pragmatic solutions with IoT. But the glue that ties it together and connects IoT devices to people, enterprises, and trading partners is Process Automation – especially through digitizing and automating processes that involve People, Enterprise Applications, and IoT devices. The top and most important level in any meaningful enterprise architecture with IoT is business process automation and collaboration.

This article was originally published on https://www.linkedin.com/pulse/intelligent-process-automation-things-ipaot-dr-setrag-khoshafian/.